An adequate securing of the load unit is always a basic requirement for an effective load security.

The components to be used for load security depend on the respective problem. Hereto basics are anti-slip mats, lashing straps and dunning bags.

In the field of lashing strap there are multi-way ratchet systems and one-way lashing systems. It is rigged either by direct lashing (diagonal lashing or head lashing) or by tie-down lashing. When direct lashing is used the load is directly held by the strength of the lashing strap. When tiedown lashing is used the load is secured by increasing the pressure on the cargo area and thereby increasing the friction.

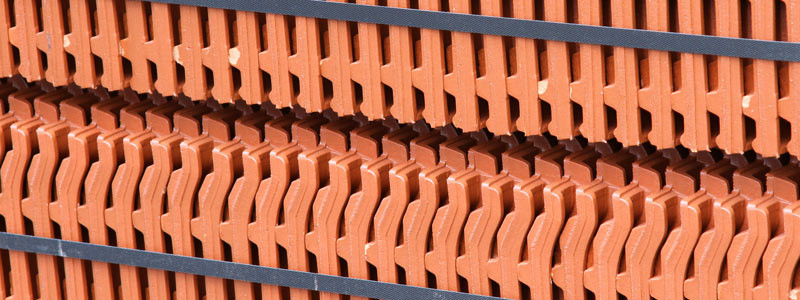

One-way lashing straps are closed with buckles. The rigging takes place by separate tensioners. The handling of one-way lashing is very easy. It is important, however,

that the used components (strap / buckle / hook) are tuned to each other and that they are also suitable to the respective lashing possibilities (the stability of the anchor points among others). There must be also used suitable tensioners which allow to raise the necessary pretension for optimum securing.